From Classroom to Circuitry: A Guide to Accelerated Electrical Training

Why Accelerated Training Works: Roadmap, Outcomes, and Relevance

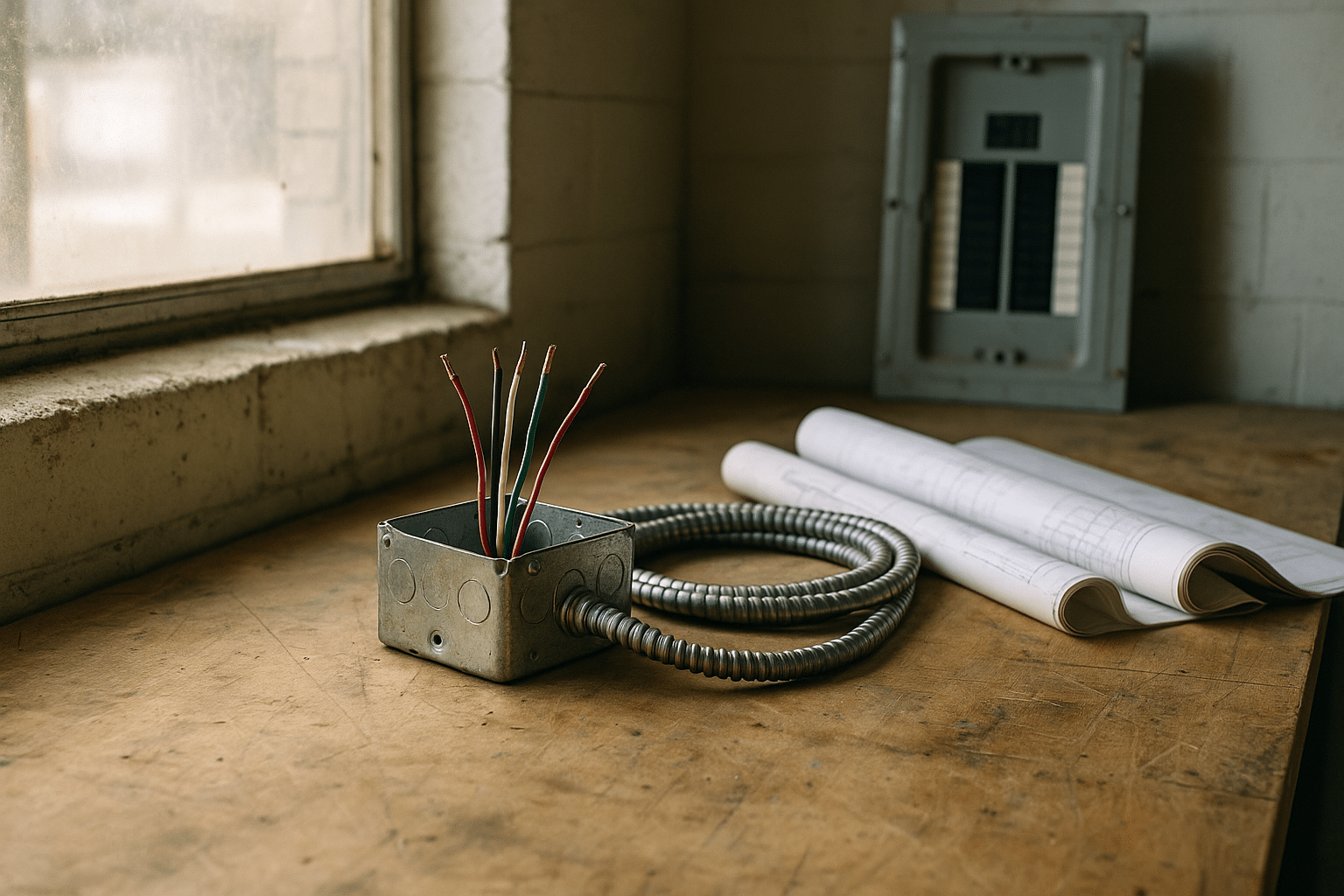

Accelerated electrical programs compress high-value learning into focused modules that mirror the pace and priorities of modern job sites. The aim is not to skip fundamentals but to remove drift, so each hour advances skills you can use immediately. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople. That tight arc—from theory to practice—prepares learners to interpret requirements, install with care, and verify results against objective measures. When courses treat the lab as a scaled job site, students practice not just tasks but decision-making: reading a plan, choosing a method, and documenting work so inspectors and teammates can follow the thread.

Outline of this guide:

– Section 1 sets the stage for fast-track learning and why it aligns with industry expectations.

– Section 2 explains NEC compliance as a practical workflow from planning to inspection.

– Section 3 details safety protocols that protect people and property while increasing efficiency.

– Section 4 breaks down blueprint reading to turn lines and symbols into a buildable installation.

– Section 5 integrates these skills into a repeatable routine for readiness and career momentum.

Relevance cuts across three domains. First, compliance: the National Electrical Code defines a shared language for safety and performance, and accelerated programs teach students to think in that language. Second, safety: any schedule advantage disappears after a single incident, so protocols become daily habits, not occasional checklists. Third, blueprint literacy: plans are the bridge between a designer’s intent and a technician’s hands. When trainees learn to see patterns—load groupings, routing corridors, and equipment clearances—they stop improvising and start anticipating. The result is work that passes inspections while minimizing rework. Good training builds judgement: when to say “proceed,” when to say “pause,” and when to say “we need clarification.”

NEC Compliance: From Principles to Daily Practice

NEC compliance begins with scope and definitions, then moves into application. Treat it as a map: articles outline what must be protected, where protection is required, and how materials and methods must perform. A practical workflow helps: plan the system, select conductors and protection, route raceways, terminate correctly, label clearly, and verify with inspection-grade tests. Think in risk terms: shock, arc, heat, and fault current. The code is designed to reduce each of these risks through consistent rules for clearances, grounding and bonding, overcurrent protection, and equipment ratings.

Consider everyday examples. Continuous loads are commonly treated at 125 percent for conductor and overcurrent sizing, which guards against heat buildup. Voltage drop recommendations often target about 3 percent for branch circuits and about 5 percent overall for feeders and branch circuits, keeping equipment within expected performance. Protective devices should match the conductor ampacity and equipment interrupt rating; downstream devices must coordinate so that a fault does not cascade and darken an entire system. Grounding versus bonding is another cornerstone: grounding connects to earth for reference and lightning or surge paths, while bonding ties metal parts together to ensure a fault finds a low-impedance path that trips a device promptly.

Common pitfalls include misapplied GFCI and AFCI protection, overfilled boxes and raceways, improper support and securement of cables, and missing working clearances around equipment. A compliance mindset turns these into checkpoints:

– Locate all areas where personnel, moisture, or kitchens and baths require special protection.

– Verify box fill using conductor volume allowances; do not ignore device yokes and equipment grounds.

– Confirm enclosure working clearances—depth, width, and height—before the first conduit lands.

– Check terminations for conductor size, temperature ratings, and torque values per equipment markings.

– Document panel directories accurately so circuits can be traced during commissioning and maintenance.

Interpreting code changes is part of professional growth. Instead of memorizing every line, learn patterns: new technology often leads to expanded protection requirements; energy efficiency pushes conductor sizing and routing practices; and emerging loads like EV charging call for dedicated branch circuits and load management planning. Keep a personal code log—questions, rulings from inspectors, and jobsite lessons—to build your internal index. The goal is consistency: installations that pass on first inspection because they are designed, built, and labeled with the code in mind from the beginning.

Safety Protocols: Culture, Procedures, and Practical Scenarios

Safety is a discipline before it is a checklist. On a real job, delays, tight spaces, and competing trades can crowd out caution, which is when habits matter most. Build a culture where verifying de-energized status, testing tools before and after use, and respecting boundaries are routine, not exceptions. Organize work so hazards are controlled in layers: eliminate when possible, substitute safer methods, engineer barriers, set administrative rules, and finally, use protective equipment. This hierarchy keeps the focus on hazard reduction rather than relying solely on personal gear.

Core protocols translate directly into field decisions:

– Establish and maintain approach boundaries around live parts; do not enter without justification and preparation.

– De-energize whenever feasible, then verify absence of voltage with a properly rated meter on a known live source before and after testing.

– Use protective equipment matched to the task: insulated tools, eye and face protection, hand protection, and footwear with appropriate traction and electrical ratings.

– Keep work areas orderly; clear exits, dry footing, and proper lighting reduce slips, trips, and missteps with energized equipment.

– Inspect ladders, cords, and temporary power distribution daily; protect cords from damage and ensure ground-fault protection on portable circuits where required.

Consider a scenario: installing a new feeder in an active panel. Planning starts with a lockable means to prevent operation of the upstream device and clear communication with the site lead. The team verifies the work scope, confirms drawings, examines available fault current and equipment ratings, and sets boundaries so others do not wander into the area. Tool selection includes a meter of suitable category rating, insulated drivers, and torque tools to meet termination specifications. With conductors landed, each termination is torqued to the manufacturer’s values and rechecked, the panel directory updated, and a final visual inspection verifies spacing, securement, and wire management. The outcome is not luck; it is a chain of controlled steps that reduce uncertainty at each handoff.

Safety also includes health over the long term. Rotating tasks limits repetitive strain, scheduled breaks help maintain focus around energized equipment, and hydration matters in warm environments where heat can impair judgement. Mentoring amplifies safety culture: pairing newer trainees with experienced technicians spreads tacit knowledge—how to listen for a subtle arc buzz, how to sense a tool slipping before it happens, and how to pause when a detail feels off. The quiet decision to slow down for thirty seconds can spare hours of rework and protect careers.

Blueprint Reading: Turning Lines, Symbols, and Notes into Installations

Blueprints are the narrative of a project told through scale, symbols, and layers of intent. Start with the index and general notes to understand scope; then move to floor plans, reflected ceiling plans, single-line diagrams, schedules, and details. Learn the graphic conventions: wiring symbols, device callouts, equipment tags, and detail bubbles reference where to find the next level of information. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople. Reading a plan is an act of navigation—identifying the destination (equipment), the route (raceways and cable paths), and the checkpoints (junction boxes, panels, and terminations).

Effective blueprint reading follows a repeatable process:

– Review the legend so symbols are unambiguous before you start counting anything.

– Trace major feeders on the single-line first to understand sources, panels, and distribution.

– Identify branch circuits by area; group loads to visualize routing corridors and shared pathways.

– Check schedules for equipment ratings and mounting requirements to plan clearances and supports.

– Verify dimensions against the scale; use consistent takeoff methods to avoid quantity drift.

Scaling matters. Whether using a physical scale or digital tools, confirm the printed scale matches the stated scale; minor differences can accumulate and distort conduit lengths, cable orders, and hanger counts. Collision avoidance is another key skill: reconcile electrical plans with structural, mechanical, and architectural drawings so conduits do not conflict with beams, ducts, or fire protection. Mark routes early and note elevation changes where necessary, especially in crowded ceilings. When plans evolve—as they inevitably do—document revisions cleanly and keep a running list of affected circuits and quantities so procurement and installation stay aligned.

Translate drawings into field-ready steps by making “install packets” for each area: a concise set of marked plans, a materials list, and a sequence of tasks. Note critical dimensions, working clearances for serviceable fronts of equipment, and any special supports. Device layouts benefit from mock-ups: tape locations on walls or floors to confirm heights, spacing, and accessibility before boxes are mounted. Keep a clean record of deviations that arise in the field so the final as-built drawings reflect reality. This discipline pays off at inspection and during maintenance, when efficient troubleshooting depends on drawings that match what is actually in the walls and ceilings.

Integration and Readiness: Practice Routines, Assessments, and Career Momentum

Mastery comes from a loop: plan, execute, verify, and improve. Set weekly practice goals that combine all three pillars—code, safety, and plans. For instance, choose a room from a plan set, perform a quick load check, pick devices and cable or conduit, route paths on paper, and write a short method statement that includes safety steps and testing checkpoints. In a lab or workshop, build a representative segment: a panel stub, a few circuits, boxes at measured heights, and a device schedule. Test continuity, polarity, and protection, then compare against your method statement to see what you missed.

Assessment should be multi-angle:

– Knowledge checks with scenario questions that force you to pick the right code concept, not just recite article numbers.

– Practical exams with a time box to simulate jobsite pace without sacrificing safety steps.

– Peer reviews where classmates inspect each other’s builds and documentation for clarity and compliance.

– Reflection logs where you capture what surprised you, what slowed you down, and what you will do differently next time.

Career readiness includes soft skills that make technical ability visible. Learn to brief a supervisor in thirty seconds: the task, the risk, the mitigation, and the expected result. Practice clear labeling and tidy work; organized installations and accurate records build trust with inspectors and clients. Build a small portfolio: photos of your lab builds (with no sensitive information), sample takeoffs, and a couple of concise write-ups linking code requirements to installation choices. Seek feedback early from experienced electricians; their practical insight turns rules into judgement and transforms checklists into intuition.

Finally, protect your momentum. Schedule consistent study sprints for code reading, rotate through safety drills so they stay fresh, and read plans daily until symbols feel like a second language. When these habits fuse, you will find that compliance, safety, and blueprint literacy are not separate courses but one continuous skill set. Accelerated training is effective because it makes that fusion happen sooner, with discipline and focus guiding every wire you pull and every decision you sign off.