Electrician Certification 101: Curriculum, Safety, and Licensing

Outline

– Why electrical work matters: safety, reliability, and efficiency

– Residential wiring: circuits, materials, layouts, and common upgrades

– Commercial systems: distribution, three-phase, load management, and documentation

– Conduit bending: math, tools, technique, and quality control

– Safety and code: permits, inspections, and testing

– Certification and licensing: pathways, exams, and career outlook

Introduction

Electric work powers daily life, yet the decisions behind every outlet, sensor, and light are part physics, part craftsmanship, and part regulation. Whether you are preparing for certification or sharpening field skills, understanding how residential wiring differs from commercial systems—and how conduit bending ties projects together—will raise both quality and confidence. The following sections unpack methods, compare options, and highlight practices that pass inspections and stand the test of time.

Residential Wiring Fundamentals: Circuits, Materials, and Layout Strategy

Residential wiring aims to deliver safe, reliable power without clutter, confusion, or unnecessary cost. The work begins with a service assessment—panel capacity, grounding and bonding integrity, and space for future circuits. From there, planning centers on loads and usage patterns: kitchens with multiple small-appliance circuits, dedicated circuits for laundry and HVAC, and lighting layouts that balance illumination with energy efficiency. Conductors are typically copper for branch circuits, sized to current and run length, with aluminum occasionally used for feeders when sized and terminated appropriately. Cable choice often favors nonmetallic-sheathed cable in wood-framed homes and metal-clad cable or conduit in locations needing added protection. Box fill calculations, device ratings, and arc-fault and ground-fault protection complete the safety picture.

Strong layouts anticipate convenience and maintenance. Grouping circuits by room makes troubleshooting faster, and labeling each breaker clearly supports future upgrades. Receptacle spacing targets practical use, reducing extension cord reliance. Kitchens often benefit from split receptacles or multiple circuits near countertops; garages and exterior locations get weather-resistant devices and appropriate covers. Voltage drop matters on long runs; limiting it to a modest percentage helps motors start smoothly and lighting stay bright. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Consider a modest renovation. A living room may need a 15–20 ampere general lighting circuit with arc-fault protection, while a workshop in the basement might demand dedicated 20 ampere circuits for tools plus additional lighting. Safety devices are nonnegotiable. Tamper-resistant receptacles protect families; ground-fault protection belongs near water sources; and bonding of metal piping, enclosures, and grounding electrodes reduces shock risk. Attention to detail—tight terminations, correct device orientation, consistency in conductor colors—builds professionalism.

– Plan for at least two small-appliance circuits in busy food prep areas where local code requires it.

– Use weather-resistant, tamper-resistant, and appropriate covers in damp or outdoor locations.

– Keep junction boxes accessible; never bury splices behind finish surfaces.

– Document circuit numbers on the panel schedule and mirror them on device covers during rough-in.

Commercial Systems: Distribution, Three-Phase, and Documentation Discipline

Commercial electrical design scales up load, complexity, and accountability. Instead of only a few high-demand appliances, a commercial facility might support HVAC plants, elevators, data systems, lighting controls, and process equipment. The distribution tree commonly includes service equipment feeding switchboards or panelboards with selective coordination across overcurrent devices. Three-phase power supports motors and balances loads more efficiently, reducing conductor size for equivalent power and smoothing current draw. Fault currents can be significantly higher than in homes, demanding careful short-circuit and interrupting rating checks for gear and breakers.

Load calculations consider demand factors and diversity, acknowledging that not all equipment runs at full load simultaneously. Lighting density targets efficiency while meeting task needs and egress requirements. Emergency systems, backed by battery units or generators, ensure safe evacuation and continuity of critical operations. Specifications often call for metal raceways for durability and grounding continuity, cable tray for large conductor bundles, and segregated pathways for fire alarm, data, and control. Commissioning and as-built documentation matter as much as installation quality; owners rely on accurate records for future maintenance and expansions. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Field realities bring unique constraints. Conduit routing must respect structural members, seismic restraints, and plenum rules. Equipment clearances protect workers and reduce arc-flash risk, with labeled approach boundaries and PPE categories derived from calculation or equipment labeling. Lighting controls might employ occupancy sensing and daylight harvesting to curb energy use without sacrificing comfort. In tenant improvements, coordination with other trades avoids clashes: ductwork, sprinklers, and cable trays all compete for overhead space. Documentation habits—panel schedules, feeder verification, torque logs, and test reports—speed turnover and prevent callbacks.

– Balance phases to keep neutral currents reasonable and limit voltage imbalance on three-phase gear.

– Verify breaker and bus ratings against available fault current; coordinate upstream/downstream devices to local requirements.

– Separate life-safety circuits from normal power and document them clearly on one-line diagrams.

– Keep an up-to-date submittal log and as-built set to reflect every field change.

Conduit Bending: Math, Craft, and Field Checks for Clean Runs

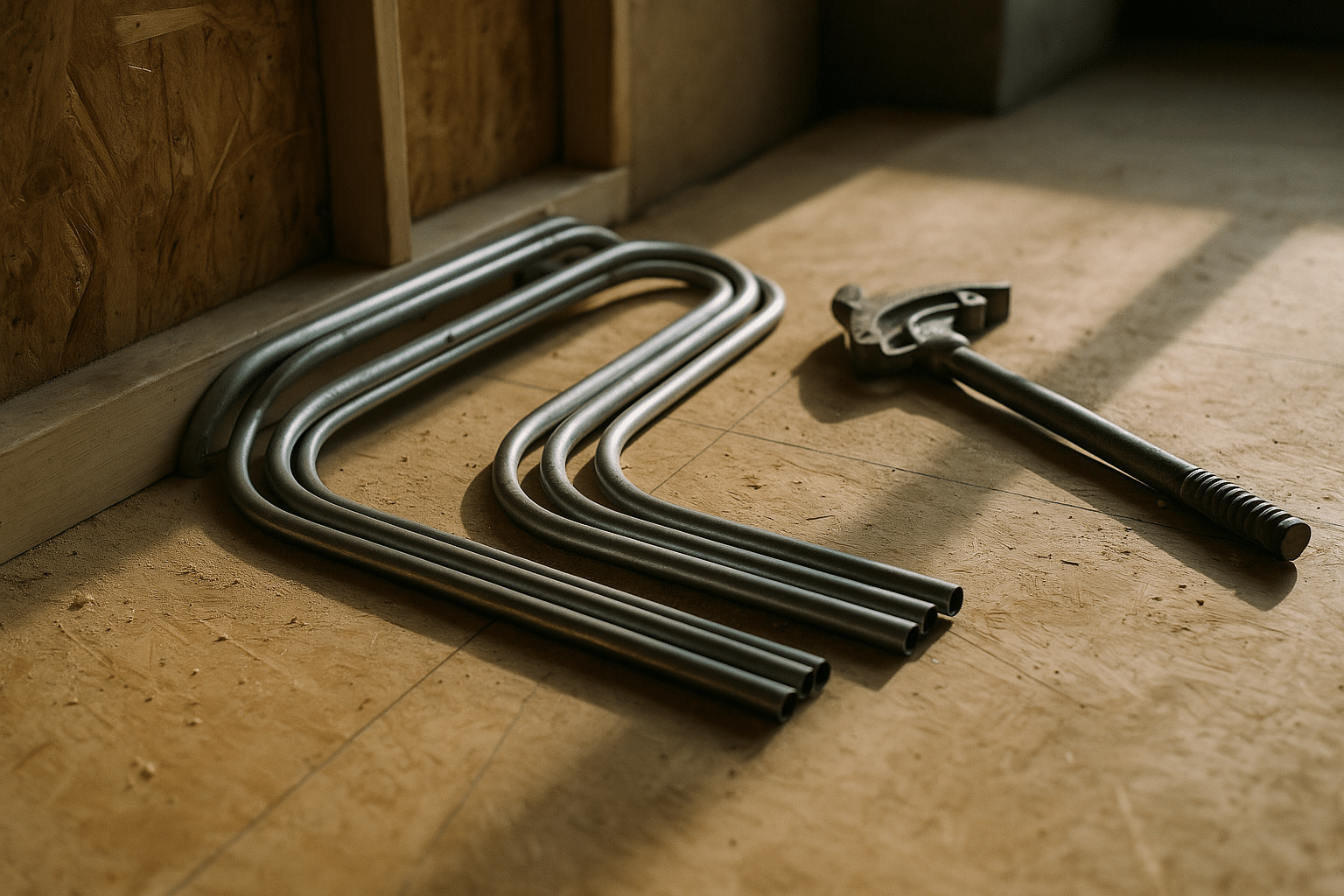

Conduit bending blends geometry with a steady hand. Clean offsets, saddles, and sweeps create pathways that look orderly, pull smoothly, and meet code-mandated bend and fill limits. The basic moves include: a simple 90-degree bend with a measured take-up; an offset to bridge obstacles; and three- or four-point saddles to cross larger obstructions while keeping the run level. Benders vary by conduit type and size, and each tool has its own markings for angle, star, and take-up references. Before bending, pros map the route on the floor or framing, measuring center-to-center distances and obstructions precisely to avoid cumulative errors.

Math guides accuracy. The offset travel equals the offset height multiplied by a handy multiplier: approximately 2.0 for 30 degrees, 1.4 for 45 degrees, 1.2 for 60 degrees, and about 2.6 for 22.5 degrees. Allow for shrink—the slight length loss in offsets and saddles—by adding a small correction before your first bend. Maintain minimum bend radius specified by code to protect conductor insulation and ease pulling; too-tight bends increase friction and risk damage. Conduit fill rules protect against overheating and abrasion: one conductor up to roughly half the cross section, two around a third, and more than two at approximately two-fifths. In practice, that often translates to choosing the next conduit size when adding even a small number of additional conductors. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Quality control is visible at a glance. Parallel runs should track evenly with consistent spacing, supported at code-compliant intervals, and leveled so couplings line up in a straight visual line. Set-screw fittings must be tight, threads properly engaged on threaded systems, and bushings installed to protect insulation at sharp edges. After pulls, megger or insulation resistance tests can verify conductor health before terminations. A neat installation speeds future additions: spare conduits or pull strings now are cheaper than ceiling rework later.

– Mark measurements on the floor and on the conduit before the first bend to avoid compounding errors.

– Keep bends in the same plane by using a level and aligning bender marks consistently.

– Deburr cuts; sharp edges nick insulation during pulls and shorten cable life.

– When in doubt, upsize conduit to respect fill, ease pulling, and plan for expansion.

Safety, Code, and Inspections: From Permit to Final Test

Safety underpins every step, from planning to energization. A hazard assessment at the start of each shift reinforces awareness of live circuits, suspended loads, and confined spaces. Lockout/tagout isolates energy sources; test-before-touch verifies that circuits are de-energized; and appropriate PPE—gloves, eye protection, arc-rated clothing where required—adds a final layer of defense. Good housekeeping reduces trip hazards and prevents damaged insulation. On ladders and lifts, fall protection and equipment inspections are routine, not optional. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Code compliance begins with clear drawings and a permit. Rough-in inspections check boxes, routing, supports, and conductor protection before walls close. Inspectors look for proper conductor sizes, grounding and bonding continuity, correct device placement, and labeling. In commercial jobs, additional reviews may focus on emergency circuits, fire alarm separation, and mechanical coordination. Final inspections verify device tightness, torque on lugs, and functional tests on lighting controls, receptacles, and equipment. Documentation—cut sheets, torque records, test results, and panel schedules—reduces uncertainty and shows diligence.

Testing is the truth-teller. Continuity checks confirm splices; polarity tests ensure hot and neutral aren’t reversed; and ground impedance tests assess fault-clearing potential. Where appropriate, insulation resistance testing reveals damage hidden by visual inspection. Load measurements after occupancy highlight opportunities to re-balance phases or adjust settings for efficiency. A commonsense principle applies: if you measured it, label it; if you labeled it, keep the record accessible for the next person who opens the panel.

– Use checklists for rough-in and final to ensure no step slips through the cracks.

– Verify torque with a calibrated tool; “tight enough” by feel varies too much.

– Keep work areas clean; debris in panels or boxes invites future faults.

– Photograph concealed work and store images alongside as-builts.

Certification, Licensing, and Your Next Step: A Practical Wrap-Up

Credentials open doors by proving competence to clients, employers, and inspectors. Paths vary by region, but most combine classroom instruction, supervised field hours, and an exam that tests code, theory, and practical application. Apprenticeships build muscle memory and judgment that books can’t. Study habits matter: break the code into digestible parts, tab frequently used articles, and drill calculations until the process becomes second nature. Mentorship accelerates growth—ask why a decision was made, not just what to do next. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Licensing tiers typically progress from apprentice to journeyman to master, with continuing education to keep pace with evolving standards and technology. Employers value technicians who document well, communicate clearly with other trades, and deliver tidy, inspectable work the first time. For individuals shifting from residential to commercial, start with small service calls in light commercial spaces, then move to larger projects with experienced supervision. Meanwhile, keep honing conduit skills—the ability to visualize routing and bend accurately remains a career-long advantage.

As you move forward, treat every installation as both a learning opportunity and a signature. Put safety first, respect the code as the baseline rather than the finish line, and choose materials suited to environment and use. Build a small library of references and your own notes; the fastest solution on the next job usually comes from something you measured, drew, or labeled on the last one. With steady practice and thoughtful preparation, certification and licensing become milestones on a broader journey toward craftsmanship and trusted service.

– Set a weekly study target and track problem areas to focus review time effectively.

– Shadow experienced installers during commissioning to learn test sequences and documentation habits.

– Keep a personal checklist for rough-in, trim-out, and final—adapt it as you encounter new scenarios.