How to Shop Clearance Sale Kitchen Equipment Smartly

Introduction and Outline

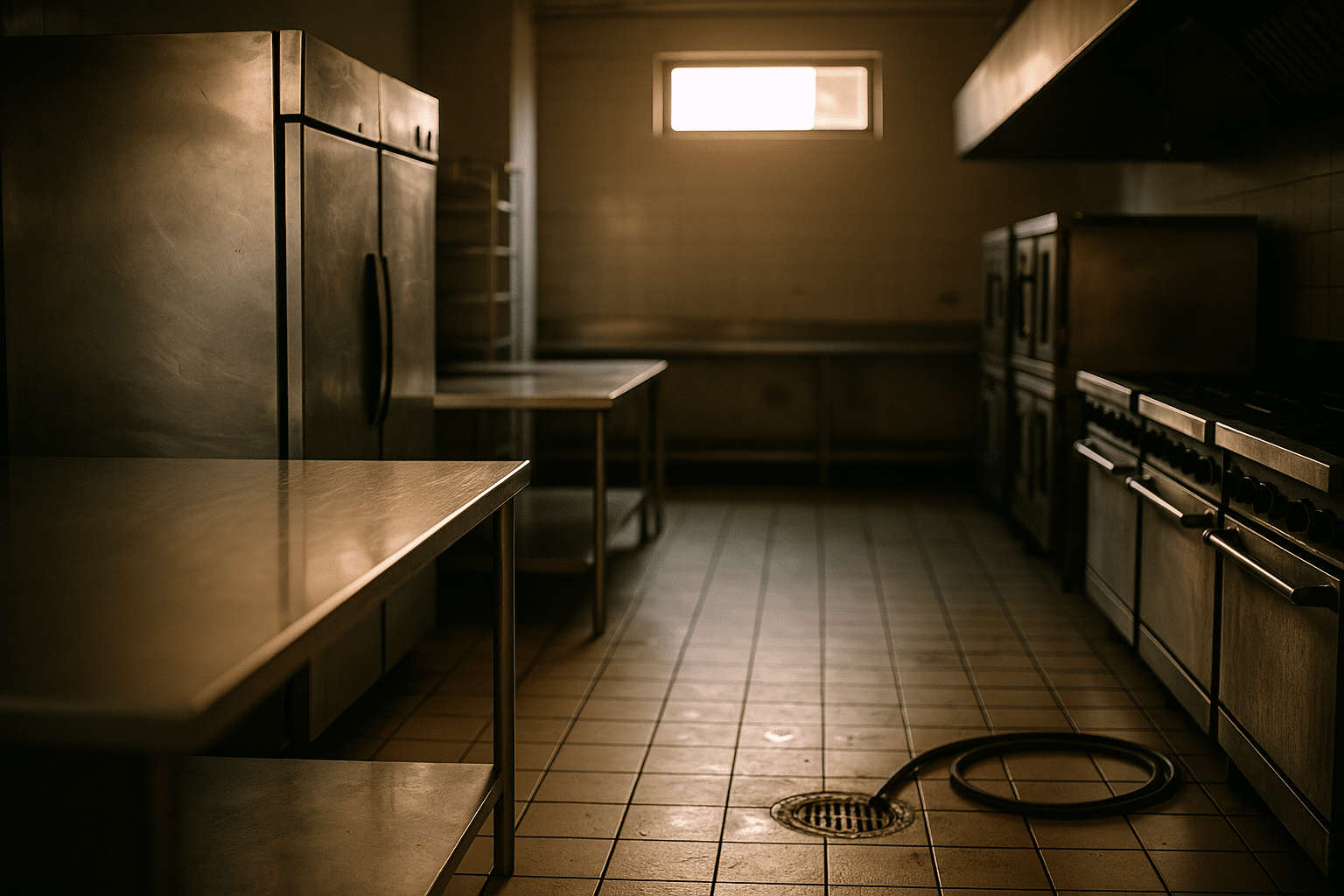

Outfitting a kitchen is equal parts arithmetic and artistry. Margins are thin, heat is relentless, and every piece of equipment must earn its space on the line. Clearance sales and commercial-grade appliances promise real savings and throughput, yet the wrong choice can turn into downtime, rising utility bills, and repairs that outstrip the discount. This article charts a practical route from intention to installation, showing how to balance price with performance and safety with speed, so your operation runs like a steady simmer rather than a rolling boil.

To set clear expectations, here is the roadmap we will follow before diving deep into each part:

– Scope: What “clearance” really means, why items are discounted, and how to decode the fine print.

– Fit-for-purpose: How commercial kitchen appliances differ from consumer units in duty cycles, capacity, and compliance.

– Smart buying: Steps to evaluate total cost of ownership, negotiate, and plan for maintenance.

– Risk management: Safety checks, utility requirements, ventilation, and workflow design.

– Implementation: Delivery paths, installation timelines, staff training, and post-purchase follow-up.

We will move from the principles of clear-eyed selection to scenario-based comparisons, layering in practical checklists you can adapt to your space. Expect numbers where they clarify trade-offs, pragmatic advice drawn from common service calls, and a few creative flourishes to keep the reading lively. Whether you are launching a small bakery counter, refreshing a food truck, or scaling a multi-station line, the goal is the same: dependable equipment that supports consistent quality without straining the budget.

Clearance Kitchen Equipment: What to Check Before You Check Out

Clearance equipment is not synonymous with “problem equipment.” Items land on the clearance rack for many reasons: packaging damage, discontinued models, floor samples, client returns within the trial window, or seasonal overstock. The opportunity is straightforward—capital savings of 20–60% are plausible—yet the homework must be meticulous. Start by matching the machine’s intended duty to your daily volume. A lightly used pro-grade mixer may outlast a new light-duty unit, while a discounted fryer with an aging thermostat could offset its purchase savings through inconsistent recovery times and extra oil consumption.

Inspection should be systematic. Look for gasket elasticity on doors, uniform door alignment, smooth drawer tracks, intact insulation around cabinets, and even coloration on heating elements. Spin fan blades gently to check for rubbing, listen for steady compressor hums without clicking, and verify that drain lines are clear. Surface wear is acceptable; corrosion around seams, pitted interiors, and warped racks signal deeper issues. Ask for a power-on test with a thermometer and a timer: time-to-temp and recovery-to-temp are far more telling than a shiny exterior. On moving parts, confirm the presence of safety interlocks and that they actuate reliably.

Documentation is your ally. Request service logs, parts availability estimates, and any remaining warranty. Many clearance items carry shorter coverage; factor that into the price. If a unit is discontinued, verify that consumables—gaskets, filters, elements—remain stocked by third-party suppliers. Calculate the total cost of ownership for at least one year: purchase price plus estimated utilities, initial parts refresh, and labor. A 40% discount can evaporate if energy use is 10–15% higher and your duty cycle is long.

An overview of how clearance kitchen equipment is commonly discussed, including inspection tips, warranties, safety factors, and value considerations.

Quick pre-purchase checklist you can adapt on the spot:

– Electrical or gas requirements match your site’s supply and local codes.

– Dimensions fit doorways, turns, and the final footprint with airflow clearances.

– Heat or moisture output will not overwhelm existing ventilation.

– Critical wear components are either recently replaced or readily sourced.

– Test results meet spec for time-to-temp, recovery, and stable holding.

Commercial Kitchen Appliances: Capacity, Compliance, and Consistency

Commercial appliances differ from home units in three decisive ways: sustained duty cycles, recoverability under load, and compliance with food-safety and electrical safety standards. In practice, that means thicker-gauge metals, higher-capacity elements or burners, more robust refrigeration compressors, and safety guards and cutoffs designed for busy, multi-operator environments. When you compare a commercial oven to a domestic one, it is not just about peak temperature; it is about how quickly the oven rebounds after multiple door openings and whether heat distribution remains even across racks during rushes.

Right-size capacity by estimating peak demand, not average demand. A small cafe might target 40–60 covers per hour at peak, while a quick-service line might push far higher. Aim for equipment that operates between 50–80% of its rated capacity at peak; this keeps recovery brisk and extends lifespan. Undersizing leads to bottlenecks and quality drift, while oversizing can inflate energy bills and slow preheat cycles. Use simple math: if a griddle can handle 20 standard patties in a six-minute cycle, that is roughly 200 per hour under ideal conditions; add a buffer for real-world delays and product mix.

Energy use and utilities deserve equal attention. High-efficiency fryers, for example, often reduce oil consumption by 20–40% through improved heat exchange and sediment management, which also supports consistent coloration and texture. Energy-efficient refrigeration can trim electricity by 15–25% via advanced insulation and variable-speed compressors, and better door gaskets reduce frost build-up. If your local utility publishes on-peak and off-peak rates, map major heating and cooling loads to your service hours to forecast operating expenses more realistically.

Compliance and safety are non-negotiable. Confirm that surfaces are smooth and cleanable, with minimal seams where food soil can lodge. Check that guards, micro-switches, and emergency stops are intact and that labels for clearances and service panels are legible. Plan your ventilation and fire suppression around heat and grease output—solid-fuel, high-BTU, or heavy-fry programs may require specific hoods and filters. Documentation should include installation guides, wiring diagrams, gas pressure specs, and maintenance intervals. A machine that is “good on paper” but lacks clear guidance can cost you hours of technician time during commissioning.

Buying Kitchen Equipment Smartly: From Shortlist to Service Ticket

Begin with a requirements brief. Write down your menu, projected peak throughput, available utilities, and footprint constraints. Rank tasks by impact on revenue and quality—if crispy fries and fast tickets define your brand identity, prioritize fryer performance and hood capacity over a showpiece range. With this clarity, assemble a shortlist across three price tiers: new, refurbished, and clearance. For each candidate, gather spec sheets and note duty ratings, cycle times, and cleaning requirements. A good purchase decision often comes from comparing like-for-like on the specific metrics that matter to your line.

Run a simple total cost of ownership estimate to avoid false economies:

– TCO (12 months) ≈ Purchase + Installation + Utilities + Consumables + Planned Maintenance + Expected Repairs − Resale Value.

– Assign conservative numbers. For utilities, multiply rated kW or BTU by estimated hours of use and your tariff.

– For maintenance, include quarterly cleanings for fryers and refrigeration coil service; for high-heat ovens, budget for door gaskets and calibration checks.

– If clearance, increase the repair contingency modestly unless parts are recently replaced and widely available.

Warranties and service access shape outcomes more than many first-time buyers expect. Limited coverage on major components like compressors, heating elements, and control boards can shift the financial balance. Confirm response times for service partners, stock levels for common parts, and whether remote locations carry surcharges. Negotiate delivery dates and installation responsibilities clearly. Tight doorways, stairwells, and narrow corridors can add surprise labor; measure your route twice, then tape the floor to confirm the final footprint and swing clearances around doors and drawers.

Financing should mirror your growth curve. Leasing spreads cash flow and may include maintenance, but can cost more over time; cash purchases avoid finance charges but demand discipline for upkeep. Consider phased upgrades: stabilize your cold chain first if spoilage is a persistent risk, then tackle high-heat production to unlock ticket speed. Lastly, prepare your team. Create quick-reference cleaning guides, schedule a training session on day one, and set calendar reminders for filter changes and temperature calibrations. A thoughtful handover turns a purchase into performance.

Conclusion: A Practical Path to Affordable, Reliable Kitchens

There is a certain poetry to a well-tuned kitchen—fans humming, stations sequenced, and plates moving with rhythm. Yet that elegance rides on choices made long before the dinner rush: what to buy, when to buy it, and how to keep it humming. Clearance opportunities can stretch a budget without stretching patience, provided you verify condition, confirm parts pipelines, and test performance against your menu’s demands. Commercial-grade appliances, chosen for capacity and recovery rather than curb appeal, will shield you from the hidden costs of slow tickets and inconsistent textures.

If you manage a cafe, a ghost kitchen, or a neighborhood bistro, adopt a playbook you can reuse with every purchase:

– Define throughput targets and station roles before shopping.

– Compare units at the metric level—recovery times, utility draw, and cleanability—not just sticker price.

– Inspect methodically and budget for maintenance from day one.

– Align delivery logistics, ventilation, and utilities before installation.

– Train staff and track performance so small drifts are corrected early.

Think of the process as mise en place for your capital plan. A measured shortlist, a realistic TCO, and a calm negotiation will nearly always outperform impulse buying. When clearance stock appears, you will already know whether it fits your workflow and your numbers. When you need the staying power of new gear, you will know which specs matter and which are window dressing. In both cases, you are buying time, consistency, and fewer service calls—the quiet ingredients behind loyal guests and steady margins. Choose deliberately, maintain faithfully, and let the line sing.