Electrician Certification 101: Curriculum, Safety, and Licensing

Outline:

– Residential Wiring Essentials

– Commercial Electrical Systems and Design

– Conduit Bending Fundamentals

– Safety, Testing, and Inspection

– Licensing Roadmap, Continuing Education, and Conclusion

Residential Wiring Essentials: Safe, Code-Aligned Power for Everyday Spaces

Residential wiring is the quiet backbone of modern comfort. From a smart thermostat’s low-voltage run to the laundry room’s 240-volt circuit, each conductor, connector, and device must be selected and installed with purpose. The heart of most homes is a split-phase service that delivers two 120-volt legs and one neutral; common 15-amp lighting circuits use 14 AWG copper, while kitchen and laundry receptacle circuits typically run at 20 amps on 12 AWG to support higher demand. Ground-fault and arc-fault protection are now widespread requirements in living spaces and wet areas, reducing risk from shock or damaged cords. Planning starts with load calculations—square-foot lighting allowances, fixed appliances, and continuous loads—so panel capacity and circuit counts aren’t guesswork.

Material choices affect performance and longevity. Copper conductors offer strong conductivity and durability; aluminum may be used in larger feeders when permitted but demands proper terminations and antioxidant compounds. Cable types differ by application: nonmetallic sheathed cable for most dry, concealed areas; metal-clad cable or conduit for exposed or high-traffic paths. Junction boxes must remain accessible, splices need mechanical integrity and appropriate wire connectors, and conductor color coding aids future troubleshooting. In practice, labeling circuits and documenting device locations pay dividends during renovations or service calls. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Good residential installations balance protection, convenience, and aesthetics. Place receptacles to reduce the need for cords across floors. Separate lighting and receptacle circuits to minimize nuisance trips. For bathrooms and kitchens, dedicated small-appliance circuits keep hair dryers and microwaves from starving the rest of the branch circuit. A few practical habits help:

– Verify box fill using conductor and device counts so the enclosure isn’t overcrowded.

– Support cables within prescribed distances of boxes and along runs to prevent strain.

– Bond metal boxes and devices consistently for a reliable fault path.

– Test polarity, GFCI/AFCI operation, and continuity before closing walls.

When done well, residential wiring fades into the background—quiet, compliant, and ready for decades of service. When rushed, it telegraphs problems: dimming lights on startup, warm devices, tripping breakers, and mystery junctions hidden behind drywall. Discipline, documentation, and adherence to adopted codes turn a jumble of cables into a clean, maintainable system.

Commercial Electrical Systems and Design: Scaling Up Power, Control, and Reliability

Commercial facilities raise the stakes on voltage, system coordination, and life-safety integration. Instead of primarily 120/240-volt split-phase, many buildings run 208Y/120 volts for receptacles and lighting or 480Y/277 volts for large motors and efficient lighting. Three-phase distribution improves motor performance and reduces conductor sizes for the same power. Designers account for demand factors, diversity in operating schedules, and future expansion: a restaurant’s evening peaks diverge from an office tower’s daytime load profile. Service entrances, main distribution boards, panelboards, and step-down transformers are laid out to minimize voltage drop, limit fault energy in occupied zones, and maintain clear working space.

Compared to homes, commercial code requirements emphasize egress illumination, emergency and standby power, selective coordination, and labeling for rapid maintenance response. Life-safety circuits are often segregated into dedicated raceways and enclosures; emergency lighting and exit signs must remain energized via battery units, inverters, or generators during outages. Motor control centers house starters, variable frequency drives, and overload protection, enabling precise control and better energy use. Lighting control systems—daylight harvesting, time schedules, occupancy sensors—help meet energy codes without sacrificing comfort. Data and low-voltage systems add complexity: structured cabling, intrusion detection, and fire alarm pathways must be routed and protected with clear separation from power conductors as required.

Field execution is as important as design. Consistent equipment grounding and bonding reduce dangerous potential differences across metallic structures. Labeling helps technicians isolate the right feeders under pressure. Harmonics created by nonlinear loads can overheat neutrals and transformers; specifying K-rated transformers or appropriately sized neutrals mitigates those issues. Commissioning walks verify that breakers coordinate, transfer switches operate, and emergency lighting reaches the required illumination levels. For maintenance, thermographic scans of switchgear can reveal loose lugs, while periodic torque checks and cleaning extend service life. In short, commercial systems are less about “bigger wire” and more about orchestrating power, protection, and human safety in busy, high-stakes spaces.

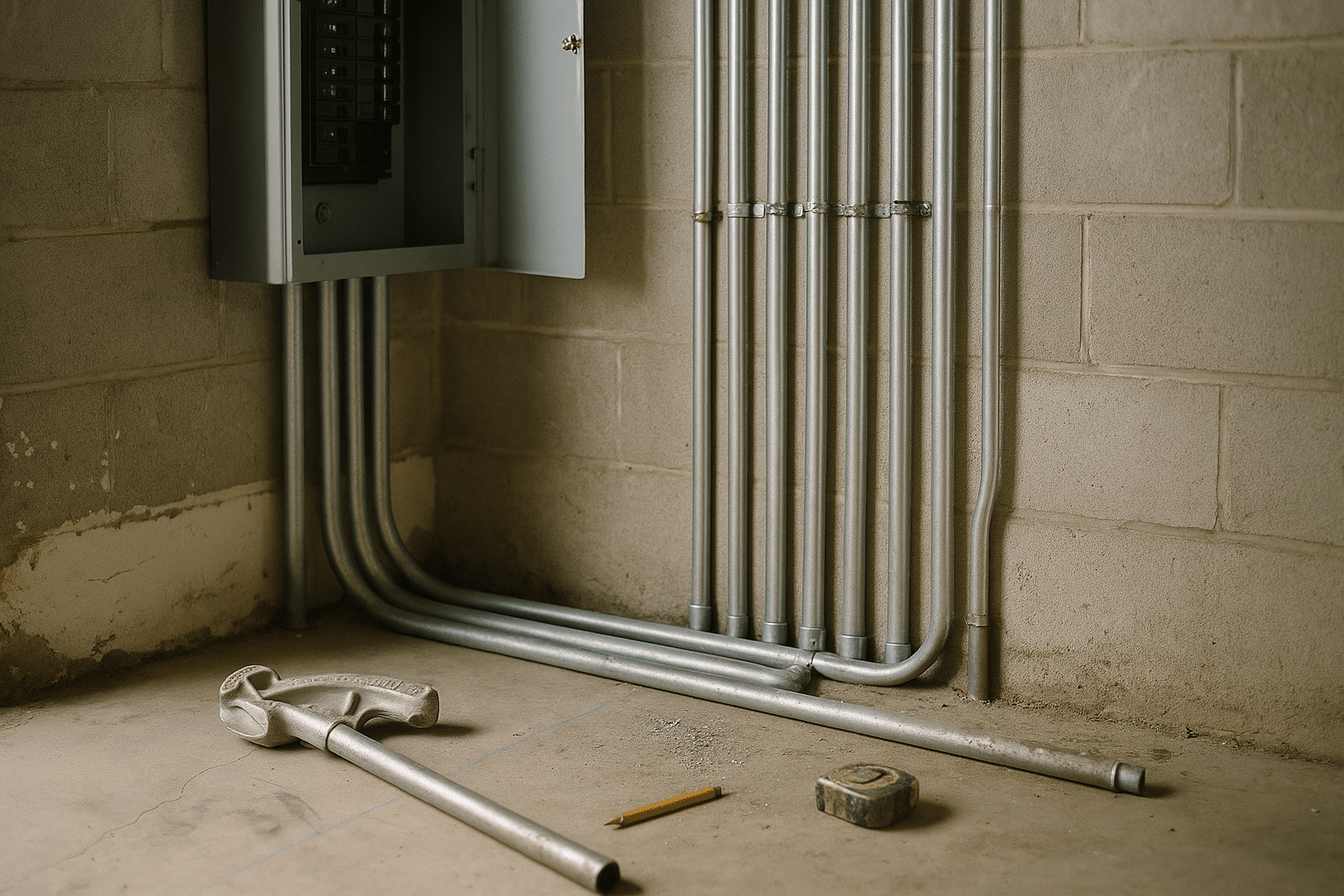

Conduit Bending Fundamentals: Clean Paths, Protected Conductors

Conduit bending blends geometry and craftsmanship. Electrical metallic tubing offers light weight and easy hand bends; rigid and intermediate metal conduits add strength and corrosion resistance; PVC works in wet or corrosive environments with solvent-welded joints and heat-formed bends. The goal is consistent: maintain conductor integrity by respecting minimum bend radii, avoid kinks and flattening, and route efficiently to conserve material. A tidy raceway plan keeps pulls manageable and simplifies future additions. Hand benders, hickeys, and hydraulic benders each have a place, but the tape measure remains the essential instrument.

Every bend type has a method. For offsets that jump a small obstruction, use consistent angles—30° and 45° are common—to keep math predictable. Multipliers help determine the distance between marks: many field charts use 2.0 for 30° offsets and roughly 1.4 for 45°, providing a quick way to translate obstacle height into bend spacing. Bending induces “shrink,” pulling the run slightly shorter; installers account for this with rules-of-thumb (for example, a 30° offset may shorten the run by about a quarter inch per inch of offset, depending on conduit size). Three-point saddles straddle a larger obstacle; ensure the center bend mirrors the side bends, and keep total degrees reasonable to ease cable pulling. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Precision shows up in small decisions. Mark the arrow, star, and rim notches on your bender so your crew shares a common language. Deburr cut ends before threading or coupling to protect insulation. Keep bends within manufacturer and code allowances to avoid increasing pull tension or damaging jackets. A few field notes to keep bends crisp:

– Make test bends on short scrap to confirm take-up and actual angle on your specific bender.

– Use a level during offsets and saddles so parallel segments read true.

– Limit total bends in a single run to keep pull friction reasonable.

– Plan junction boxes at logical intervals for pulling and future reroutes.

The result is both functional and architectural—clean verticals along a masonry wall, parallel horizontals under a mezzanine, arcs that look intentional instead of improvised. When the light hits a neat rack of EMT, the math and muscle behind each bend become quietly evident.

Safety, Testing, and Inspection: From PPE to Documentation

Safety starts before the ladder leaves the van. De-energize circuits whenever practical, verify absence of voltage, and apply lockout/tagout so switches don’t surprise you mid-task. Personal protective equipment—safety glasses, gloves rated for the task, arc-rated clothing when required—fits the job, not the other way around. Many jurisdictions align with recognized standards for shock and arc-flash risk assessments; labels at panels and switchboards inform approach boundaries and PPE levels. Good housekeeping reduces hazards as effectively as high-tech gear: dry floors, tidy cords, and clear exit paths make incidents less likely and responses faster.

Testing elevates workmanship from “seems fine” to “proven.” A basic toolkit detects common issues: a multimeter for voltage and continuity, a clamp meter for load and inrush, a non-contact tester for quick checks, a receptacle analyzer for wiring errors, and an insulation resistance tester when commissioning long or critical runs. Continuity and polarity tests confirm that neutrals and grounds haven’t been crossed. Insulation resistance readings, taken before energizing, expose nicked jackets or moisture intrusion that would otherwise surface as nuisance trips. For larger systems, commissioning steps include verifying breaker settings, simulating generator transfers, and confirming emergency lighting illuminance levels along egress paths.

Inspection is a partnership, not a showdown. Clear labeling, accessible junctions, neat conductor makeup, and accurate one-line diagrams make the inspector’s job straightforward and reflect a culture of quality. Documenting load calculations, panel schedules, torque values, and test results builds a service record that benefits both the owner and future electricians. Consider adding simple checklists to close every job:

– Terminations torqued to manufacturer specs and rechecked after initial load.

– GFCI/AFCI devices tested and logged with date.

– Panel directories updated with precise circuit descriptions.

– Photos of concealed work added to the project file for reference.

With these habits, safety becomes routine. And when something does go wrong, the combination of training, documentation, and the right instruments turns unknowns into solvable problems. Reliable, verifiable work is the hallmark of a professional who leaves systems safer than they found them.

Licensing Roadmap, Continuing Education, and Conclusion

Licensing gives structure to a career that blends craft and responsibility. Many regions follow a progression from apprentice to journeyman to master, with on-the-job hours and classroom training measured in thousands of hours. Apprenticeships often total around 8,000 hours of supervised field work paired with 600–1,000 hours of coursework over several years. Exams evaluate code knowledge, calculations, and practical judgment. Continuing education keeps credentials current as codes evolve and technologies change—think rapid updates to lighting controls, energy storage, and electric vehicle infrastructure. Discover the core modules of 6-month electrician courses, including wiring basics, code compliance, and safety training for aspiring tradespeople.

Creating a learning plan helps you grow intentionally. Mix formal classes with field challenges: lead a small residential remodel, then shadow a commercial service change to see three-phase gear up close. Build a portfolio of details—panel schedules you reorganized, a conduit rack you laid out with minimal waste, troubleshooting notes that traced a phantom trip to a shared neutral. Soft skills accelerate your path: clear jobsite communication, accurate timekeeping, and precise material lists reduce delays and earn trust. Ethical practice—quoting transparently, documenting changes, respecting adopted codes—wins repeat work more reliably than any slogan.

Conclusion: Whether your next project is a kitchen remodel or a distribution upgrade on a busy retail floor, the same principles apply—plan carefully, install neatly, test thoroughly, and document everything. Residential wiring rewards attention to detail; commercial systems demand coordination and foresight; conduit bending turns math into clean lines that make future maintenance easy. Training and licensing convert experience into recognized competence, giving clients and inspectors confidence in your work. With steady practice and curiosity, you’ll turn each job into a case study that strengthens the next—and the one after that.